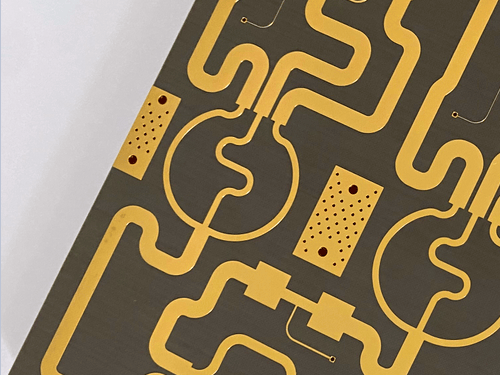

TLY-5 2-Layer 10mil High-Frequency Thin PCB with Immersion Gold

1.Introduction

TLY-5 laminates are manufactured with very lightweight woven fiberglass and are much more dimensionally stable than chopped fiber reinforced PTFE composites. The woven matrix in the TLY-5 material yields a more mechanically stable laminate that is suitable for high volume manufacturing. The low dissipation factor enables successful deployment for automotive radar applications designed at 77 GHz as well as other antennas in millimeter wave frequencies.

2.Key Features

Dielectric constant of 2.2 with tight tolerance 0.02 at 10 GHz/23°C

0.0009 loss tangent at 10GHz

Density (specific gravity) of 2.19 g/cm3

Moisture Absorption 0.02%

CTE in X-axis of 26 ppm/°C, Y-axis of 15 ppm/°C and Z-axis of 217 ppm/°C

3.Benefits

Dimensionally stable

Lowest DF

Low moisture absorption

High copper peel strength

Uniform & consistent DK

4.PCB Construction Details

| Specification | Value |

|---|---|

| Base Material | TLY-5 |

| Layer Count | 2 layers |

| Board Dimensions | 55mm × 50mm (±0.15mm) |

| Minimum Trace/Space | 6/8 mils |

| Minimum Hole Size | 0.2mm |

| Blind Vias | No |

| Finished Board Thickness | 0.3mm |

| Finished Cu Weight (Outer Layers) | 1oz (1.4 mils) |

| Via Plating Thickness | 20 µm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | No |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper layer 1 – 35 µm

TLY-5 – 0.254 mm (10mil)

Copper layer 2 – 35 µm

6.PCB Statistics:

Components: 9

Total Pads: 41

Thru Hole Pads: 23

Top SMT Pads: 18

Bottom SMT Pads: 0

Vias: 17

Nets: 2

7.Typical Applications

Automotive Radar

Satellite/Cellular Communications

Power Amplifiers

LNBs, LNAs, LNCs

Aerospace

Ka, E and W band Applications

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide